The traditional steel cutting ceremony was held at Navantia UK’s Appledore shipyard in North Devon today, marking a significant achievement for the FSS programme that is driving a £100m investment across Belfast and Appledore. The steel cutting ceremony, led by Minister for Defence Readiness and Industry Luke Pollard MP, officially kicked off the start of the construction of the first FSS ship – RFA Resurgent.

Navantia press release

Commodore Sam Shattock, Head of Royal Fleet Auxiliary Service, revealed the name of the first ship as RFA Resurgent. The ceremony was attended by the Navantia UK workforce along with apprentices and representatives from Ministry of Defence Equipment & Support (DE&S), the RFA, Royal Navy, government and industry. UK suppliers to the FSS programme as well as local businesses supplying to the Appledore shipyard were also in attendance.

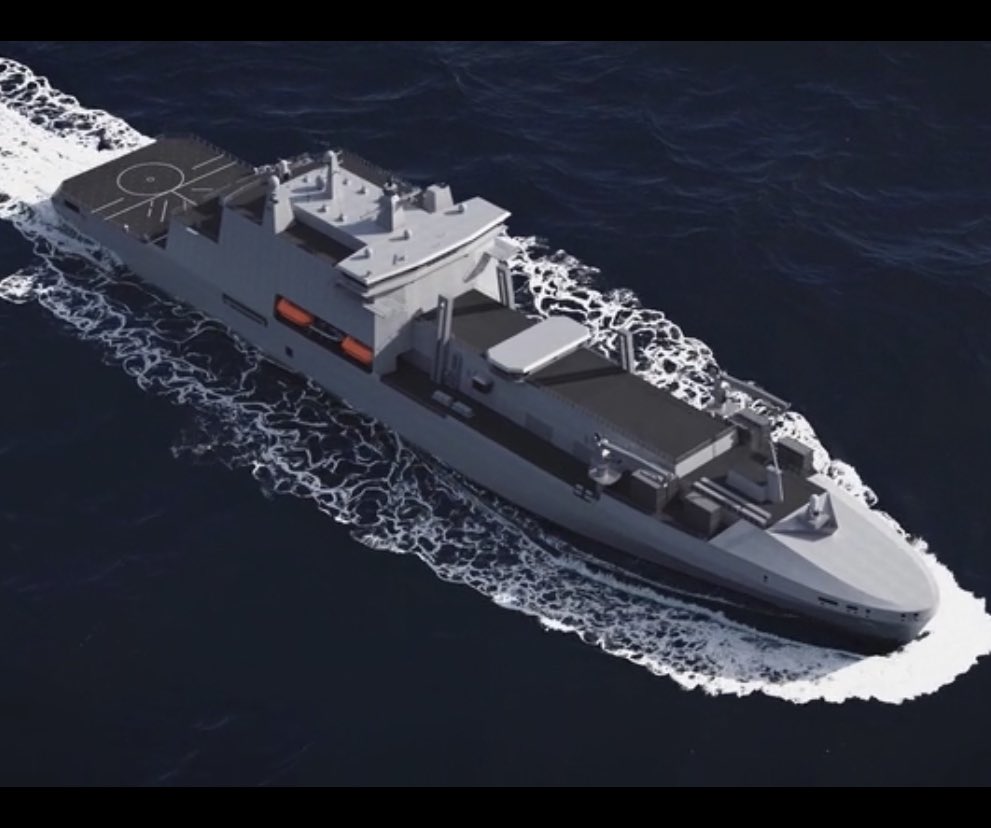

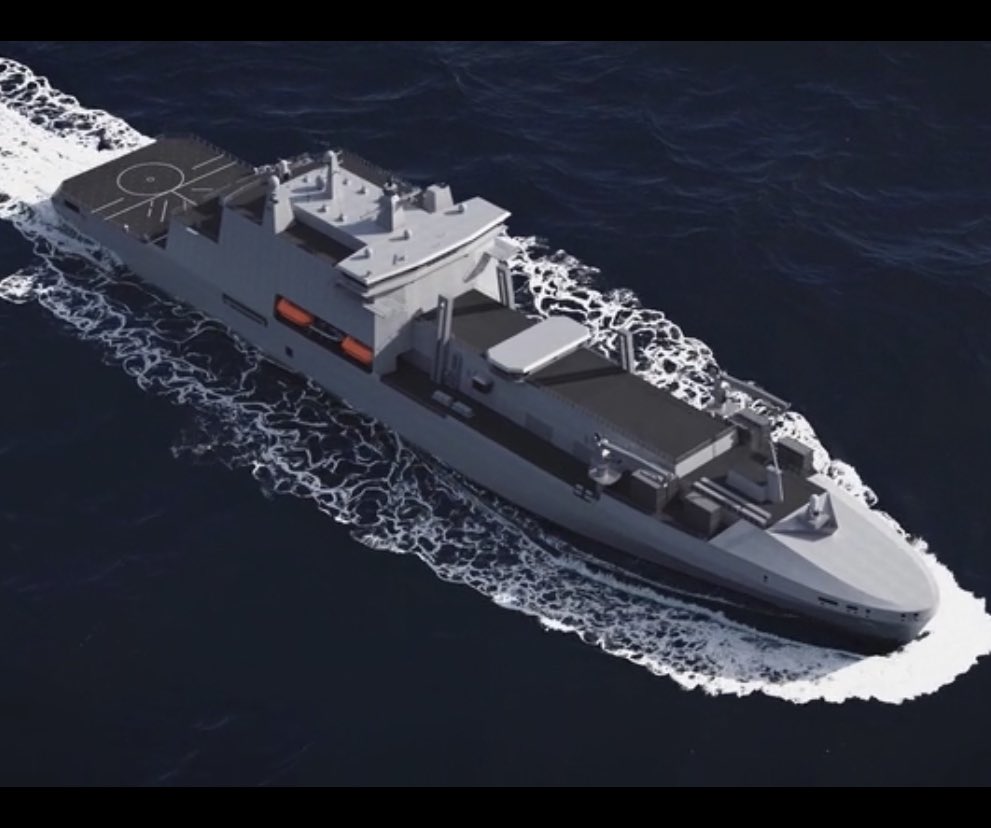

Each ship will be 216 metres long – the length of two Premier League football pitches – and will provide munitions, spares, food and other essential stores to naval vessels at sea. This new capability will enhance defence operations, ensuring the Royal Navy can remain at sea for prolonged periods without returning to port.

Donato Martínez, CEO of Navantia UK, said: “Across our yards, we have worked tirelessly to mark today’s milestone. It is a proud day for the whole team, whose commitment has brought us to this point. The FSS programme continues to deliver on two fronts: critical capability for the Royal Fleet Auxiliary, and long-term sovereign industrial capacity for the UK through investment in infrastructure, technology and skills. Today’s steel cut is evidence of what we have been saying all along. When we make a commitment to deliver, we do so.”

Minister for Defence Readiness and Industry, Luke Pollard MP said: “This is a significant moment as we begin the build of the RFA’s newest ship that will keep our Royal Navy ready to fight and able to deter future threats. By backing British shipbuilding, we are creating more than 1,200 skilled jobs in Devon, Belfast and beyond. This shows defence is as an engine for growth, boosting communities across the UK. In a new era of threat, we are investing more of a rising defence budget in new platforms and technologies.”

Commodore Sam Shattock, Commodore RFA, said: “The ship is innovative, meets the latest environmental protection standards and is designed from the bottom up to deliver maritime sustainment as efficiently as possible. The construction will provide impetus to the UK ship building industry, supporting jobs and local economies at the various construction and assembly locations in the UK. I’m excited to watch this ship join the RFA flotilla and demonstrate its capabilities in due course. A true warfighting enabler for the Royal Navy of tomorrow.”

Keith Bethell, DE&S Director, Maritime Environment, said: “This is a significant moment for everyone involved in the delivery of this programme. The FSS ships represent a major investment in the RFA’s ability to support frontline naval forces globally. Each vessel will serve as a crucial supply link for carrier-led operations, proudly built by skilled workers brought together for this shared mission.”

The North Devon shipyard will construct the bow sections of the ships, which will comprise three individual blocks. Navantia UK currently employs 200 people in Appledore, including 20 new apprentices who were recruited this year in partnership with Petroc College.

The FSS programme is delivering economic growth across multiple sites, including Navantia UK’s Appledore and Belfast yards. The final assembly of the ships and construction of the mid-section of the vessels will take place at Navantia UK’s Harland & Wolff shipyard in Belfast.

Ricardo Domínguez, Navantia Chairman, said: “This partnership between Britain and Spain matters. As European nations face shared security challenges, industrial cooperation like this makes both countries stronger. It is almost a year since Appledore, Belfast, Methil and Arnish facilities joined Navantia UK. I would also like to commend the hard work of all those involved in the integration and the creation of this new actor in British shipbuilding. Today is also proof of your commitment and professionalism”,

Navantia UK investment across its four yards – Appledore, Arnish, Belfast and Methil – is one of the most significant industrial revitalisation projects in the UK, strengthening the UK’s industrial base and sovereign defence capabilities. The programme will grow the workforce in the long term, adding high-skilled jobs in computer-aided design, advanced manufacturing, and digital systems integration. As work on the FSS programme accelerates, Navantia UK aims to employ 1,500 by 2029–30, and around 2,000 by the early 2030s. Currently, Navantia UK employs 222 apprentices across its four yards, representing 20% of its workforce.

The revitalisation work across Harland & Wolff includes installation of cutting-edge equipment such as robotic plasma cutters, a fully mechanised flat panel line, and automated quality control systems. Upgrades to delivery systems, stockyard management, and digital integration are also progressing, ensuring FSS vessels can be delivered with greater speed and precision. In Appledore, investment includes new roofing and a new plasma cutter, used to cut steel today.

To achieve growth, Navantia UK is working in close partnership with local businesses, realising the UK Government’s ambition, set out in the Defence Industrial Strategy, to position defence as a key engine for growth by encouraging collaboration, boosting local economies and creating a sustainable pipeline of talent across Northern Ireland, England and Scotland.

Last month, the FSS programme achieved another critical milestone, namely, the completion of the Critical Design Review (CDR), marking the transition from design to manufacturing for the Royal Fleet Auxiliary’s next-generation support ships.

The CDR is a key stage in the shipbuilding process, essentially providing the green light to begin physical production of the three FSS ships. This comprehensive Ministry of Defence review assessed the complete, detailed design of the vessels, from hull structure to equipment fit. The Review covered overall structural integrity, safety standards, environmental sustainability, risk minimisation and military systems integration.

About the Fleet Solid Support Programme

The three FSS vessels will be the Royal Fleet Auxiliary’s modern solid stores replenishment ships, each measuring 216 metres in length – equivalent to two Premier League football pitches. They will be the largest UK military ships with the exception of aircraft carriers.

These ships will deliver vital supplies, munitions and provisions to Royal Navy warships while at sea, enhancing the UK’s carrier strike capability and supporting maritime security operations worldwide.

The FSS programme represents a dual strategic objective: delivering critical operational capability through three next generation support ships whilst simultaneously rebuilding sovereign UK shipbuilding capacity through the modernisation of UK yards, technology transfer to Navantia UK from the Navantia SA’s world-class Spanish shipyards, and workforce development.